Cooling a fluid or condensing a gas via evaporative cooling is all-natural, using water as the cooling medium and air to efficiently dissipate heat into the sky.

Evaporative cooling is a highly efficient technology. Refrigeration systems which make use of wet cooling towers contribute in the reduction of the CO2 footprint. Wet cooling towers can save an additional 56.000 tons of CO2 per year. Read more...

Advantages

- Lower cooling water temperatures can be achieved: The amount of evaporation, and hence heat transfer, depends on the wet bulb temperature instead of dry bulb temperature. Especially in the summer this wet bulb temperature is far lower than the equivalent dry bulb temperature. For example, during hot summer days with dry bulb temperatures exceeding 35°C, the wet bulb could be as low as 22°C, making it possible to cool water down to 25°C using evaporative cooling.

- Compact design: resulting in 50% area savings compared to comparable air-cooled installations. This also makes them easier to install.

- The highly efficient design consists of a more compact heat exchanger resulting in a low refrigerant charge.

- Considerable energy savings: Evaporation removes more heat in comparison to conventional air-cooled methods for heat transfer, while requiring four times less airflow. The Eurovent study provides you with clear insights on the energy saving potential of water-cooled chillers. Read here

Why go for evaporative rather than dry cooling?

- When you need a fluid outlet temperature close to the design ambient dry bulb temperature

- To save on energy costs

- If the cooling unit plan area is compact or restricted

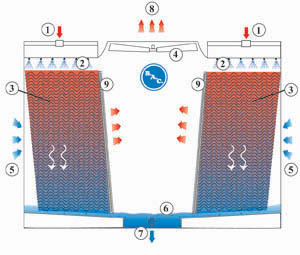

Principle of operation

The cooling process is achieved via close water/air contact, and transfer of heat to the air by small scale water evaporation. The heat is then dissipated via the warm, saturated discharge air.

Legend:

- Hot water in

- Water spray distribution system

- Heat transfer media

- Fan system

- Ambient air in

- Water collection basin

- Cold water out

- Warm saturated air out

- Drift eliminators

Evaporation of water

Evaporative cooling is accomplished by the evaporation of a small portion of water. The heat necessary for the evaporation is withdrawn from the remaining water on the heat exchange surface depending on the design principle of the wet cooling tower. Read the Eurovent recommendations on how to evaluate and minimize water consumption in evaporative cooling equipment.

Evaporative cooling products

Various types of evaporative cooling products exist, all featuring:

- a heat exchange or transfer section made constantly wetted via a water spray arrangement,

- a fan system to force or induce ambient air via the heat exchange section

- other auxiliary components such as a water collection sump, drift eliminators and controls

BAC offers the following evaporative cooling technology products:

- open cooling towers

- closed circuit cooling towers or coolers

- hybrid coolers (e.g. Nexus, HFL, HXI, HXC types of products)

- condensers

- dry coolers with adiabatic pre-coolers (common known as adiabatic coolers)

Evaporative cooling equipment is marketed in a range of sizes, from compact units that are transportable fully assembled up to huge units requiring on-site construction or assembly.

A choice of many construction materials and fan arrangements allow the designer to optimally combine performance, energy usage and service life to suit each particular application.

Want to know if evaporative cooling can help you with the heat rejection of your system? Contact your local BAC representative for more information.