Understanding adiabatic cooling: Operation and benefits

Adiabatic cooling is an efficient and environmentally friendly method used to reduce temperatures in various applications, including industrial processes, HVAC systems. Adiabatic cooling leverages the natural process of evaporative cooling to achieve temperature reduction.

Here’s how an adiabatic cooler operates and the benefits it brings to your system.

How an adiabatic cooler operates

An adiabatic cooler works by passing air through a moistened pad before it comes into contact with the heat exchange system. The operation of an adiabatic cooler can be broken down into a few key steps:

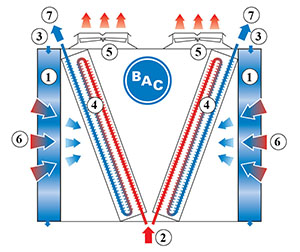

1.Pre-cooling pads; 2. Warm water/fluid in; 3. Water; 4. dry coil; 5. fan; 6. air in; 7. cold water/fluid out.

Pre-cooling phase: As warm air is drawn into the cooler, it passes through water-saturated pads. This process does not wet the surface of the heat exchanger directly; instead, the evaporation occurs in the air before it reaches the heat exchanger.

Evaporative cooling: When the warm air encounters the moistened pads, water evaporates, absorbing heat from the air. This process reduces the temperature of the air effectively and efficiently, using the latent heat of vaporization.

Heat exchange: The cooled air then passes over the heat exchanger, where it absorbs heat from the process fluid or gas within the heat exchanger coils. This transfer cools down the fluid or gas while the air warms up slightly.

Discharge: The warmed air is then expelled from the system, and the cycle continues, maintaining a constant flow of cooled air or gas through the system.

Key benefits of adiabatic cooling

Energy efficiency: Adiabatic coolers consume significantly less electricity compared to traditional dry cooling systems, as the primary cooling effect is achieved through the natural process of evaporation.

Environmental impact: This cooling method is more environmentally friendly, using water as a cooling medium instead of harmful refrigerants. Compared to dry coolers, adiabatic coolers use less electricity.

Water usage: Although adiabatic cooling requires water, it is designed to maximize water efficiency. BAC adiabatic coolers are optionally fitted with pumps for water circulation and have controls to minimize water consumption while still achieving optimal cooling.

Low maintenance: Adiabatic coolers typically have fewer mechanical components than conventional cooling systems, resulting in lower maintenance requirements and costs.

Versatility: These coolers can be used in various settings, including industrial manufacturing, data centers, and HVAC systems for buildings, offering a flexible solution for a wide range of cooling needs.

Conclusion

Adiabatic cooling presents a sustainable and efficient alternative for temperature control in numerous applications. By harnessing the natural process of evaporation, adiabatic coolers provide effective cooling with a lower environmental impact, making them an attractive option for modern cooling requirements. Whether you're looking to enhance your industrial processes or improve the efficiency of your building's HVAC system, adiabatic cooling offers a promising solution.

BAC offering

BAC provides a diverse range of adiabatic coolers and adiabatic condensers, each featuring unique advantages and accompanying accessories.

For more information on integrating adiabatic cooling solutions into your operations, contact our experts today. We're here to help you find the most efficient and sustainable cooling strategies for your needs.