Your choice of construction material is primarily determined by the :

- operating environment

- service life

- budget

Our products come in various materials. Your local BAC representative can assist you in choosing the best material option for your specific project.

The basic standard material is hot-dip galvanized steel. Featuring an excellent service life, effective maintainability and proper water treatment.

Baltiplus protection

We protect hot-dip galvanized steel with an external anti-corrosive enamel paint. Fastening hardware has a zinc phosphate organic corrosion protection. Use Baltiplus corrosion protection and

- extend the service life of the equipment

- avoid internal paint peeling

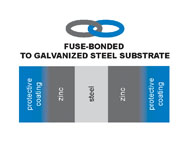

The patented new generation Baltibond hybrid coating is a unique product.

The patented new generation Baltibond hybrid coating is a unique product.

A special hybrid polymer is electrostatically sprayed onto each individual galvanized steel component for complete and uniform surface coverage. All these components then undergo a heat-activated thermosetting cure process which fuse-bonds the polymer powder to the galvanized steel surfaces.

Use the new generation Baltibond hybrid coating and:

- save money

- extend the equipment service life

- save water by applying higher cycles of concentration

- facilitate cleaning with the smooth surface finish

- respect the environment

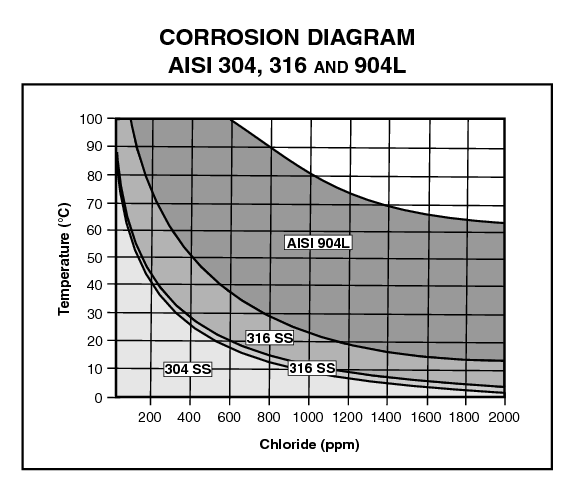

Use stainless steel for corrosion critical applications. We offer AISi 304L or 316L and recommend 316L for applications with chloride concentrations exceeding 500 ppm in the circulating water.

Use stainless steel for corrosion critical applications. We offer AISi 304L or 316L and recommend 316L for applications with chloride concentrations exceeding 500 ppm in the circulating water.

This corrosion diagram offers guidance as to which levels should be taken into account.

Component construction

For non-unit structure elements, corrosion resistant material is used, e.g. fiberglass reinforced polyester (FRP), polyvinyl chloride (PVC), aluminum or copper.

Water quality guidelines or concentration cycles differ for each material option. Check our water quality guidelines for more information.

Contact your local BAC representative for more information.