A small cost for big savings

More BAC bearing benefits

All BAC bearings are specifically designed for cooling tower application and tested in our R&D laboratories.

Longer service life

- Longer bearing L10 life of 80,000 hours compared to other bearings on the market.

- Unique specification for operation in harsh conditions, within a moist and hot environment.

Installing a BAC bearing will give you reliable operation:

- The continuous operation of the cooling tower is ensured, avoiding loss of production because of downtime.

- Frequent replacement or service work is avoided, which means you do not face this high cost.

- Your fan shaft, propeller and other drive elements can all work as they should with a BAC bearing installed, which is not the case when a non BAC bearing is installed.

Easy installation

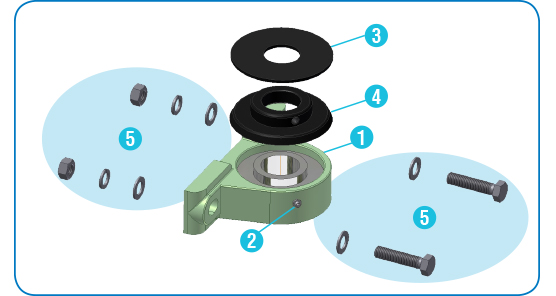

- The BAC bearing kit, supplied with the required mounting hardware, offers quick and easy installation.

Features that make our bearing unique!

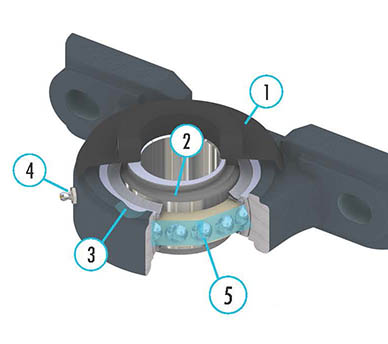

- An engineered flinger with integrated collar, specifically designed for BAC.

This rides in a special machined cross section in the housing to repel water. - A 3-piece R-seal including outboard and inboard flinger.

- Specal housing an notch, machined to prevent water collection.

- The grease fitting location is unique.

This ensures full evacuation of old, contaminated grease out of the bottom. - Grease that outperforms most common available greases.

This ensures an extended grease life and better rust resistance.

Maintenance tip !When replacing bearings, replace all bearings on the shaft together for optimum performance. Also consider replacing additional drive components, at the same time, for reduced maintenance downtime. After replacement make sure the bearings are properly greased and protect all parts with soft seal protective product. (grease cartridges and soft seal are available from BAC) |

Want to replace the bearings of your BAC cooling equipment? Contact your local BAC representative.